Eli Flex

Eli-Flex FR909/N60 Paste

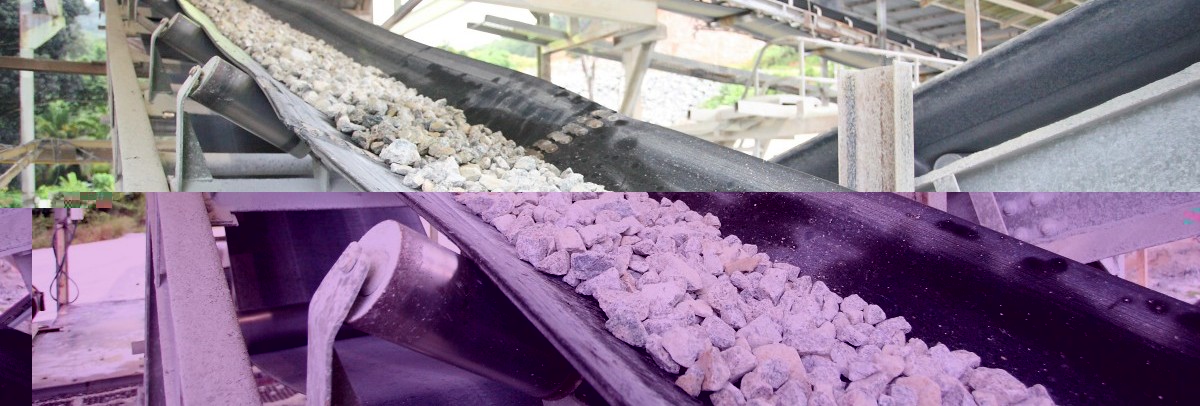

Eli Flex is an ingenious two part Polyurethane resin formulated to repair damaged conveyor belting and other Rubber products.

Designed to repair almost any rubber related conveyor belt problem including but not limited to:

- Holes

- Tears

- Cuts

- Splits

- Gouges

- Rips

- Longitudinal and lateral cracks

- Sidewall repair

- Worn edges

- Exposed fabric carcass

- Exposed steel cables

- Steel cord

- Fasteners

- Filler strips

- Worn lagging patches

- Fraying or stringing

- Rebuilding cleats

- Chevrons

- Profiles

Conveyor services U.S.A have this to say “ We always use it when we have a problem with our conveyors” and Tim McLaughlin from T Carson company says “ I’ve been in the conveyor belt maintenance business for 25 years, and Eli Flex is the best product I have ever used”

There are a host of features and benefits to using Eli Flex FR909/N60 Paste which include

- It’s easy to mix and apply – A side by side packaging solution ensures perfect mix ratio and simplifies handling and preparation

- Eli Flex paste demonstrates excellent flexibility, impact and abrasion resistance

- High tear propagation resistance

- Excellent wear

- Broad spectrum chemical resistance

- No special tools or equipment required and easy to transport

- Low irritation potential

- Liquid version can be cast, whilst the paste is applied by trowel

- Convenient packaging and 3 kit sizes including 150 g, 300 g and 500g packs

Application is a breeze, the conveyor belt or rubber surface must be clean, dry and rough (prepared prior to application)

Open the resin pack by cutting the aluminum foil along the marked lines

Once the resin pack is out of the foil sleeve, grasp both sides and gently pull apart until the separator pops up.

Carefully slide out the separator and remove the divider clip

Mix by kneading and squashing the resin pack together until it starts to warm up ( 3-4 Mins) To ensure a Homogeneous resin mix, use the plastic clip to move the resin from the corners of the resin pack towards the center.

Then cut open any corner of the resin pack, squeeze out the contents onto the damaged surface area.

Finnish off by smoothing the resin with an Eli Flex spatula or putty knife and leave to cure.

Curing @ 25°C is between 2 and 2 and a half hours, with the cure time increasing as it gets colder, with a 5 hour cure time @ 5°C

Other applications include °

- Off road Tyre repair to slow moving earth equipment – Tractors and diggers

- Patch linings in chutes, tanks and pipes

- Mending polyurethane screen decks

- Rubber castings, mouldings

- Marine fender repairs

- Vehicle anti roll bar repair in buses and trucks

For more information and pricing on the Eli Flex product please contact Polymer technologies in Perth Western Australia on + 61 08 9303 9969 or sales@polymertechnologies.com.au